Ductwork encapsulation involves sealing and protecting the ducts in a building using a special coating. This process is particularly useful in managing aging or deteriorating duct systems. The encapsulation material, typically a water-based polymer, is applied to both protect the ductwork and improve air quality by preventing fibers from escaping into the air.

When is Encapsulation Necessary?

In Homes:

Older homes often have fiberglass ducts that may start to deteriorate over time. Homeowners face two main options:

- Replacement

- Encapsulation

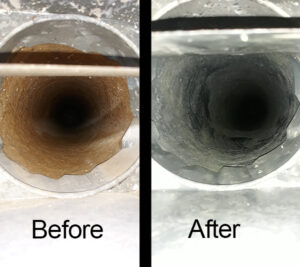

Removing these ducts can be expensive. A more economical way to go about it is to encapsulate the ductwork. We’ll apply a protective coating to make the ductwork solid and fiber-free again. But we will not do this unless we guarantee that we will get at least 95% of the ductwork. So, an inspection will need to be done to see if we will be able to access all areas.

In Businesses:

The need for encapsulation in commercial settings often arises from different scenarios. For instance, rooftop ductwork exposed to the elements may require encapsulation to prevent degradation and fiber release. Similarly, if the duct drops contain fiberglass, encapsulation might be necessary to maintain safety and functionality.

Encapsulation Materials:

The typical encapsulation agent is a duct sealer—a water-based, penetrating polymer designed to coat and seal ductwork, sheet metal, and internal fiberglass liners. This treatment not only preserves the integrity of the duct system but also enhances indoor air quality by preventing contaminants from circulating.